Washing Systems

World-class washing technology, delivered with the kind of local service global competitors can’t match.

Smart Soil Starts Here

Our washing systems are designed to efficiently process soil, slurries, and hydrovac waste materials, delivering cleaner end products and maximizing material recovery. Transform your construction waste into opportunity while getting in the clear environmentally.

Benefits that Stack Up

Economic

Reduce fees, reclaim valuable material, and improve project margins by turning waste into revenue.

Environmental

Minimize environmental risk and reduce the carbon footprint of your organization.

Operational

Reduce disposal risk and keep production moving with dependable support when you need it.

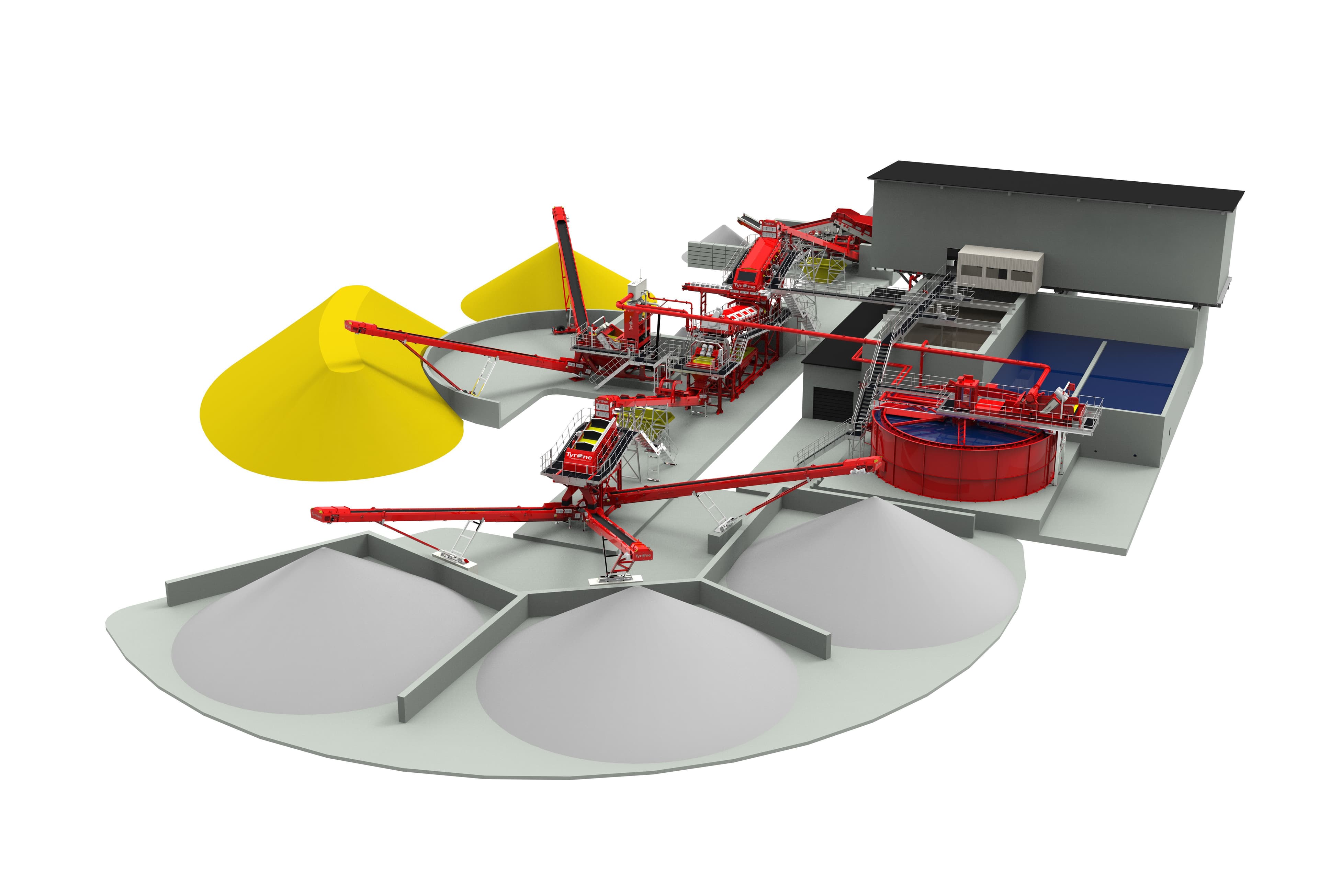

Custom Built Solutions

Every Frontline washing system is built for long-term performance and straightforward day-to-day operation. From advanced sorting and scrubbing to high-efficiency water reuse, our plants are designed to get more out of your material with less waste and less hassle.

Needs could be different, but the goal is the same: cleaner outputs, higher recovery, and an operation that keeps improving. That’s why we tailor each system to your material, throughput, and site requirements.

System Components

Screeners

Screening is the first major separation step. It uses vibrating screens to size the incoming material, removing oversized debris and splitting the remaining mix into controlled fractions so each stream can be washed, scrubbed, and classified more efficiently downstream.

Washing & Classification

The use of water and agitation to break up clays and strip contaminants from the material, then separate it into distinct streams by size and weight. Usable sand and aggregate are cleaned and recovered, while fine silts/clays are pulled off for targeted handling.

Scrubbers

Scrubbing uses high-energy mixing to break up clumps and scrub fines, clay, and light contamination off sand and aggregate. That frees up clean, recoverable material while pushing the dirty fines into the next stage for classification and water treatment.

Feeders & Stackers

Conveyors meter the right flow into each stage to prevent surges and keep performance consistent, while stacking conveyors carry cleaned products to organized stockpiles, reducing loader time, limiting cross-contamination, and maximizing site efficiency.

Water Treatment

Water and slurry treatment captures the fines and contaminants washed out of the material, then cleans and recirculates process water back into the circuit. Settling, thickening, and filtration concentrate the remaining slurry for controlled handling.

Applications

Excess Soils

Trenching, utilities, foundations, and site prep often leave crews with wet, mixed, clay-heavy material. A soil washing circuit pulls usable sand and aggregate back out, while directing fines into a controlled stream. That means fewer disposal runs, lower hauling costs, and more predictable schedules on civil jobs.

Hydrovac Waste

Hydrovac material shows up as a dense slurry of water, clays, fines, sand, and debris all in one mix. Wet processing separates that blend into workable streams, reclaiming reusable material when feasible while tightening fines control and reducing landfill reliance through smarter water handling.

Contaminated Soils

Brownfields, industrial sites, spills, and redevelopment work can generate material that isn’t suitable to move or reuse as-is. Washing splits it into managed outputs. Recovering clean fractions where possible and isolating impacted fines for focused treatment and compliant disposal.

Ready to Pick Your Plant?

Turn high-cost material into a controlled process. Whether you’re exploring feasibility or ready to design, we’ll walk through the details and the next steps. Let’s talk soil washing.